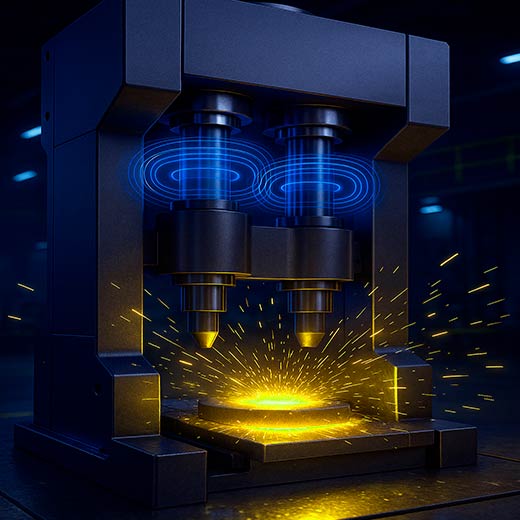

Thanks to the system’s precision and programmability, industrial presses can operate with greater efficiency, flexibility, and lower maintenance costs.

The ability to generate high-power, repetitive impacts with reduced power consumption not only optimizes productivity but also reduces the factories’ carbon footprint, aligning with the industry’s sustainability demands.

Industrial Press

The metal stamping and forming industry faces the challenge of reducing its enormous energy consumption without losing impact power.

Our magnetic technology allows for multiplying the applied force with minimal energy input, achieving impacts equivalent to those of high-tonnage industrial presses, but with a fraction of the power consumption. This represents a paradigm shift in a sector historically dependent on energy overload.

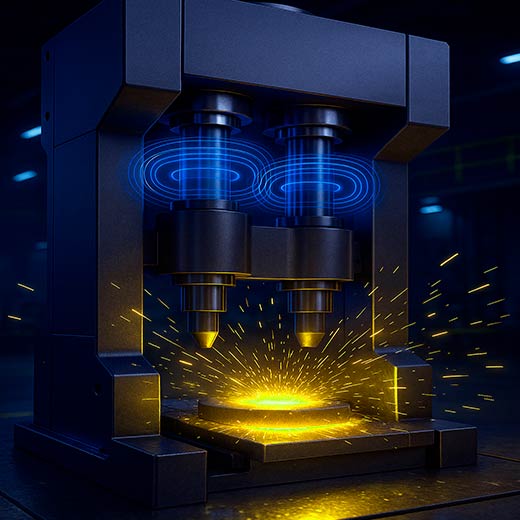

Industrial Press

Thanks to the system’s precision and programmability, industrial presses can operate with greater efficiency, flexibility, and lower maintenance costs.

The ability to generate high-power, repetitive impacts with reduced power consumption not only optimizes productivity but also reduces the factories’ carbon footprint, aligning with the industry’s sustainability demands.

The metal stamping and forming industry faces the challenge of reducing its enormous energy consumption without losing impact power.

Our magnetic technology allows for multiplying the applied force with minimal energy input, achieving impacts equivalent to those of high-tonnage industrial presses, but with a fraction of the power consumption. This represents a paradigm shift in a sector historically dependent on energy overload.